Innovations in Chemical Solutions: LSD, Halogen Free Products, Oil Soluble Dyes, and Fire Retardants

The modern chemical industry plays a vital role in supporting manufacturing, construction, textiles, plastics, electronics, and many other sectors. Among the wide range of specialty chemicals available today, LSD, halogen free compounds, oil soluble dyes, and fire retardants stand out for their critical performance, safety, and environmental benefits. These chemical solutions are engineered to meet strict industrial standards while also addressing growing concerns about sustainability, health, and regulatory compliance.

LSD, commonly known in industrial contexts as Liquid Synthetic Dye or specialized laboratory-grade solutions depending on application, is widely used in research, diagnostics, coatings, and process control. High-purity LSD formulations ensure consistent results in laboratories and manufacturing environments where accuracy is essential. Industries such as pharmaceuticals, biotechnology, and chemical testing depend on these solutions for reliable color indication, tracing, and analytical purposes. With rising demand for precision and quality control, the use of standardized LSD products continues to grow.

Halogen free materials have become increasingly important due to environmental and health regulations. Traditional halogen-containing compounds, while effective in many applications, can release toxic gases when burned and pose disposal challenges. Halogen free alternatives are designed to eliminate chlorine, bromine, and other halogens while still delivering excellent performance. These materials are widely used in electrical cables, automotive components, electronics, packaging, and construction products. By choosing halogen free solutions, manufacturers not only comply with global safety standards but also contribute to reduced toxic emissions and improved workplace safety.

Oil soluble dyes represent another crucial category of specialty chemicals. Unlike water-soluble dyes, oil soluble dyes dissolve easily in non-polar solvents, oils, fuels, waxes, and plastics. They are extensively used in industries such as lubricants, fuels, cosmetics, plastics, printing inks, and coatings. These dyes offer excellent brightness, transparency, and stability, making them ideal for applications where color consistency and resistance to fading are essential. For example, in the fuel industry, oil soluble dye help in product identification and leak detection, while in cosmetics they provide vibrant, long-lasting shades in oil-based formulations.

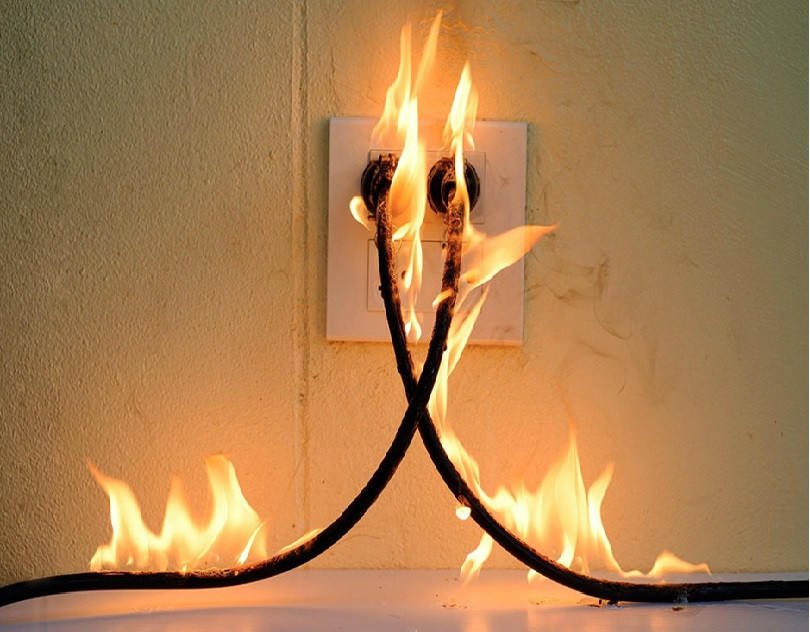

Fire retardants are essential for enhancing safety across multiple sectors, including construction, textiles, electronics, aerospace, and transportation. These chemicals are designed to slow down ignition, reduce flame spread, and limit smoke generation when exposed to fire. Fire retardants work through various mechanisms such as forming protective char layers, releasing flame-inhibiting gases, or reducing the availability of flammable materials. With rising urbanization and stricter building codes, the demand for advanced fire retardant solutions is increasing steadily. Modern fire retardants are also being developed to be halogen free and environmentally safer, aligning with global sustainability goals.

The integration of LSD, halogen free compounds, oil soluble dyes, and fire retardants reflects the chemical industry’s shift toward high-performance and eco-conscious solutions. Manufacturers are now focused on developing products that balance efficiency, safety, and environmental responsibility. Advanced research and development, combined with compliance to international standards, ensure that these specialty chemicals meet the evolving needs of global markets.

In conclusion, LSD, halogen free materials, oil soluble dyes, and fire retardants form the backbone of many critical industrial applications. From ensuring accurate laboratory processes and vibrant coloration to enhancing fire safety and reducing environmental impact, these chemicals play a vital role in modern manufacturing. As industries continue to prioritize safety, sustainability, and performance, the importance of these innovative chemical solutions will only continue to grow.

.jpg)

Comments

Post a Comment