Enhancing Industrial Performance with Liquid Solvent Dyes, Oil Soluble Dyes, and Flame Retardants

In modern industrial applications, color, safety, and performance play a crucial role in determining the quality and usability of materials. Liquid Solvent Dyes, Oil Soluble Dyes, and Flame Retardants are essential chemical components that serve these exact purposes. From creating visually appealing products to enhancing fire resistance, these specialized compounds contribute to both aesthetics and functionality across multiple industries.

The Role of Liquid Solvent Dyes

Liquid Solvent Dye /s Dyes are highly concentrated coloring agents known for their excellent solubility in organic solvents, plastics, and hydrocarbons. They are primarily used in industries such as plastics, coatings, fuels, and inks. Due to their superior color strength, high transparency, and resistance to heat and light, solvent dyes ensure uniform coloration and long-lasting brilliance. Their non-polar nature makes them ideal for coloring non-aqueous systems like lubricants, waxes, and candles. Moreover, their easy dispersion and stability offer manufacturers flexibility and efficiency in production processes.

Importance of Oil Soluble Dyes

Closely related to solvent dyes, Oil Soluble Dyes are designed to dissolve in oil-based substances such as petroleum products, lubricants, and paraffin waxes. These dyes are often used in fuel identification, oil staining, and plastic manufacturing. Their chemical stability and high solubility ensure even distribution without precipitation or fading over time. Oil soluble dye are also valued in decorative applications, where they impart vivid and consistent coloration to transparent or translucent materials. In industries like automotive, cosmetics, and textiles, these dyes enhance visual appeal while maintaining product integrity.

Flame Retardants: Ensuring Safety and Compliance

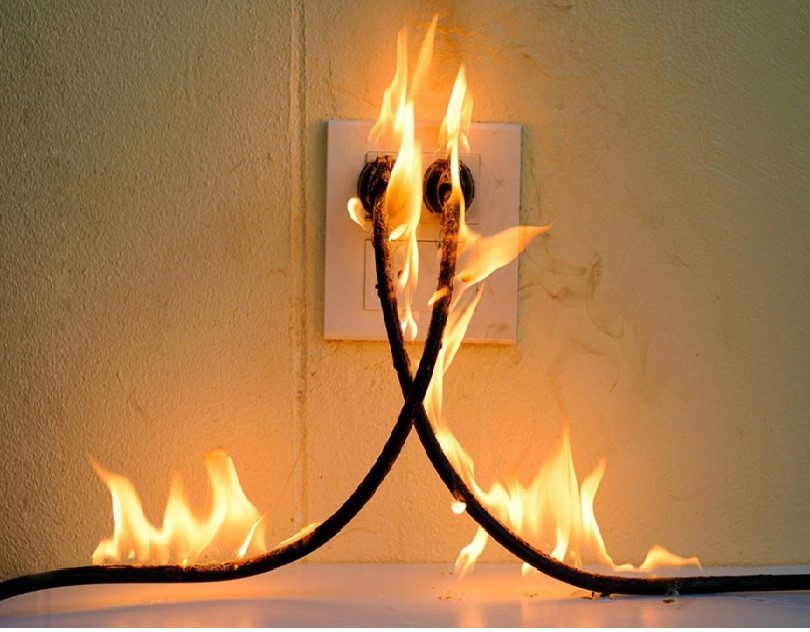

While dyes focus on appearance, Flame Retardants play a vital role in ensuring product safety. These compounds are added to materials to inhibit or delay the spread of fire. In sectors such as construction, electronics, textiles, and transportation, flame retardants help meet stringent fire safety standards. They function by either forming a protective char layer, diluting flammable gases, or interrupting the combustion process. The use of Fire Retardants significantly reduces the risk of fire hazards, offering added protection to both people and property.

Modern formulations of flame retardants are designed to be environmentally friendly, minimizing the release of toxic substances during use or disposal. Industries now prefer halogen-free alternatives, which maintain high performance while adhering to environmental safety regulations.

The Synergy Between Color and Safety

When combined strategically, dyes and flame retardants can enhance both the visual and functional attributes of a product. For example, in plastic components used in electronics or automobiles, Liquid Solvent Dyes provide the desired coloration while Flame Retardants ensure compliance with fire resistance standards. This balance of aesthetics and protection defines modern manufacturing excellence.

Conclusion

The use of Liquid Solvent Dyes, Oil Soluble Dyes, and Flame Retardants reflects the continuous innovation in chemical engineering aimed at achieving superior quality and safety. As industries evolve, these materials will continue to play a pivotal role in shaping durable, vibrant, and safe products. Whether it’s adding a rich hue to a lubricant or ensuring a material’s resistance to fire, these compounds are indispensable to modern industrial success.

.jpg)

Comments

Post a Comment